Why tougher regulations on silica are just the start

Australia’s world-first ban on engineered stone continues to be strengthened to address the broader crystalline silica risk posed by using any material, (man-made or natural) that contains more than 1% crystalline silica.1 These tougher regulations are designed to prevent the development of lung, kidney and heart diseases due to exposure to unsafe exposure to airborne crystalline silica, writes RICHARD BOLTON, Principal Occupational Hygienist at EDP Consultants.

Since the first case of silicosis from exposure to engineered or manufactured stone was identified in 2015, more than 600 Australians have been diagnosed with this serious chronic (ongoing) lung condition.2

The disease can develop after breathing in respirable crystalline silica (invisible particles less than 10 microns in size) that is released from crystalline silica-containing materials during grinding, cutting or polishing. Once inside the lungs, the particles can scar and damage the lungs, leading to a condition known as silicosis where the damage causes the lungs to be less flexible, making breathing more difficult. There is no cure for silicosis, and it can be fatal.3

While these regulations should be applauded, Australia is not done and dusted when it comes to managing the health risks associated with exposure to respirable crystalline silica. As a society, we need to introduce further clever tooling and better ventilation and extractive systems to work with materials containing crystalline silica. We need to also build on the awareness-raising efforts of our regulatory bodies, representative industry bodies, and peak health and safety organisations.

The health risks caused by exposure to respirable crystalline silica extend across many sectors including construction, mining and extractive, manufacturing, sandblasting, tunnelling, transport industry (including rail and excavation), civil construction, agriculture, utilities, concrete industry, and stone masonry.4

In the 12 years to June 2022, more than 550 workers compensation claims for silicosis were accepted in Australian states and territories.7 The Lung Foundation Australia estimates that each year up to 600,000 Australians are exposed to respirable crystalline silica dust across diverse industries.5

Further recommended worker protections

Regulators are also considering halving the workplace exposure standards (WES) to respirable crystalline silica dust from 0.05 to 0.025 mg per cubic metre (mg/m3).6 Already, the latest legislative reforms have defined a process resulting in respirable crystalline dust levels exceeding 0.025mg/m3 as a “high risk” requiring works to cease until a Silica Risk Control Plan has been implemented.7

While New Zealand has already implemented stricter (0.025mg/m3)8 regulations regarding crystalline silica exposure, there is still ongoing debate to adopting similar workplace exposure standards in Australia. Given the challenges in detecting low levels of crystalline silica with the current dust suppression and extraction technologies, it seems unlikely that we’ll be able to meet the new standard without more rigorous workplace controls.

Implementing comprehensive measures and support will help ensure that current standards are met. Regulators need to stay informed and help the industry navigate these challenges.

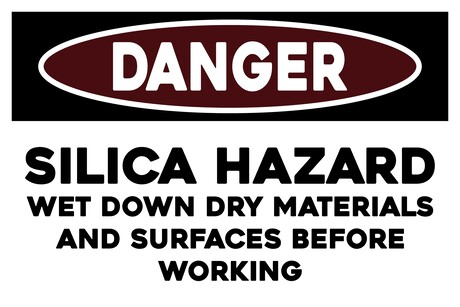

A collaborative industry-wide approach is essential to help Australians avoid exposure to respirable crystalline silica. However, as of today the most effective method to combat exposure is to avoid it altogether through strict control measures including isolating workers from dust, using enclosed cabins with high-efficiency filtration, and implementing wet dust suppression or efficient exhaust systems. When these are not feasible, workers must be properly equipped and use approved respiratory protective equipment to safeguard against inhaling harmful particles.

1. Crystalline silica and silicosis – Research into a lower workplace exposure standard and short term exposure limit for respirable crystalline silica | Safe Work Australia

2. https://lens.monash.edu/@medicine-health/2024/02/20/1386499/breathing-new-life-into-silicosis-research

3. https://www.healthdirect.gov.au/silicosis

4. https://legislation.nsw.gov.au/view/whole/pdf/inforce/2024-09-03/sl-2017-0404 and Pp 3 and 15:

5. Page 5: https://lungfoundation.com.au/wp-content/uploads/2023/10/NSPS-NAP-Fifth-Full-Draft-Copy-for-Public-Consultation.pdf

6. Crystalline silica and silicosis – Research into a lower workplace exposure standard and short term exposure limit for respirable crystalline silica | Safe Work Australia

7. https://www.safeworkaustralia.gov.au/esban/faq

8. Silica-Crystalline (all forms) | WorkSafe

Early silicosis detection — via a 5 min breath test?

A new diagnostic tool that analyses a person's breath for signs of silicosis has the...

PPE supplier's disaster preparedness gets cyclone tested

The recent Severe Tropical Cyclone Alfred led a supplier of PPE to put into practice emergency...

Since the ban: Victoria gives an engineered stone update

Since the 1 July 2024 nationwide ban on the processing, manufacture and supply of engineered...